Polyether Ether Ketone: A High-Performance Engineering Thermoplastic

|

| Polyether Ether Ketone |

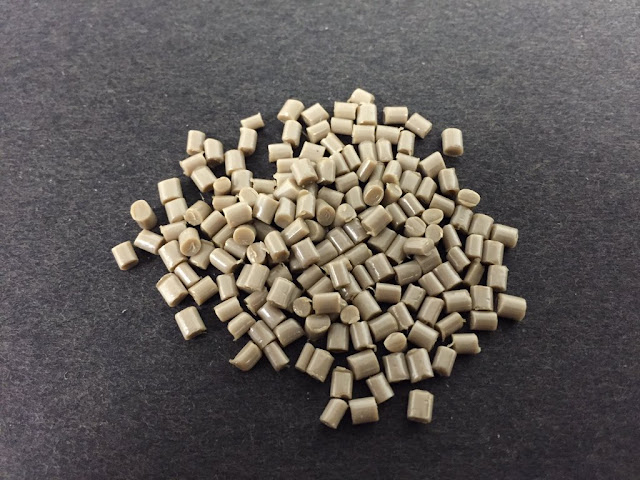

Polyether ether ketone, commonly known as PEEK, is a semi-crystalline

thermoplastic belonging to the polyaryletherketone (PAEK) family. PEEK polymer

was first developed in the late 1970s as an alternative to metal in

applications requiring high strength, rigidity and toughness at elevated

temperatures. It has excellent mechanical and chemical resistance properties which

make it suitable for use in demanding environments.

Physical Properties of PEEK

Polyether

Ether Ketone (PEEK) is known for

its high strength, stiffness and toughness even at elevated temperatures. Some

key physical properties of PEEK include:

- Density: 1.3 g/cm3, making it one of the lightest high performance polymers.

This property aids in weight reduction for parts.

- Melting Point: 343°C. PEEK retains its mechanical integrity up to 260°C and

can withstand short term peak temperatures up to 300°C.

- Glass Transition Temperature (Tg): Between 143°C to 150°C. Above this

temperature, the polymer transitions from a brittle glassy state to a rubbery

state with more impact resistance.

- Chemical Resistance: PEEK exhibits outstanding resistance to a wide range of

chemicals including organic solvents, acids, bases and salt solutions. It is

impervious to almost all chemicals except oxidizing acids.

- Excellent Dimensional Stability: PEEK has very low moisture absorption of

only 0.1-0.2% when immersed in water. This results in negligible swelling or

distortion on exposure to moisture/solvents.

Mechanical Properties of PEEK

The mechanical properties of PEEK make it a popular engineering material

replacing metals in many applications:

- Tensile Strength: Excellent tensile strength of 90-100 MPa with high retained

strength even at raised temperatures up to 150°C.

- Stiffness & Flexural Modulus: Comparable to Metals - Flexural modulus of

3.6 GPa provides strong but lightweight structures.

- Impact Strength: Outstanding toughness - un-notched Izod impact strength of

80-110 J/m. PEEK maintains impact resistance better than other thermoplastics

even at sub-zero temperatures.

- Fatigue & Compressive Strength: Superior fatigue strength and compressive

strength properties allow PEEK parts to withstand dynamic cyclic loading

conditions.

- Wear Resistance: Very low coefficient of friction of 0.25 and high abrasion

resistance. PEEK parts can be used in high wear applications.

Processing of PEEK

PEEK, being a semi-crystalline thermoplastic, can be processed like other

plastics using various manufacturing techniques:

- Injection Molding: Most common method used to manufacture complex parts in

high volumes due to PEEK's excellent flow characteristics. Cools rapidly for

net shape parts.

- Machining: Can be machined easily after injection molding using conventional

metalworking tools. Provides dimensional precision and intricate details.

- 3D Printing: Emerging as a useful technique for low volume production of

complex PEEK parts using laser sintering or powder bed fusion methods.

- Extrusion: Used to produce profiles, tubes, pipes and sheets which are further

thermoformed or welded to make finished products.

- Bonding and Joining: PEEK lends itself for adhesive bonding, welding,

screwing etc. It can also be bonded with fillers to reinforce weak areas.

Applications of PEEK

Due to its unique properties, PEEK has found diverse applications replacing

metals in industries such as:

- Aerospace: Engine components, fasteners, composites, structural frames

operating in high load/temperature environments.

- Automotive: Distributor caps, gear parts, ignition coils and valve seats for

their superior tribological properties.

- Medical: Implants, artificial joints, valves, tubes, dental brackets due to

biocompatibility and sterilization capability.

- Electronics: Insulators, semiconductor mounting brackets, wire and cable

insulation where heat and chemical resistance is critical.

- Industrial: Bearings, gears, pumps and valve components in ultra high

performance applications.

- Consumer Goods: Sports goods (tennis rackets, bicycle parts etc.), home

appliances, small industrial machines.

PEEK's excellent mechanical and chemical resistance properties along with

processability and superior performance at high temperatures, have led to its

wide acceptance as an advanced engineering thermoplastic replacing metals in

diverse industries. PEEK components deliver long-term reliability and cost

savings by reducing part counts and weight. Continued improvements in 3D

printing of PEEK will further expand its applications in the future.

Get

more insights on this topic: Polyether

Ether Ketone (PEEK)

Comments

Post a Comment