Thermal Interface Materials: Enabling Heat Dissipation in Electronics

|

| Thermal Interface Materials |

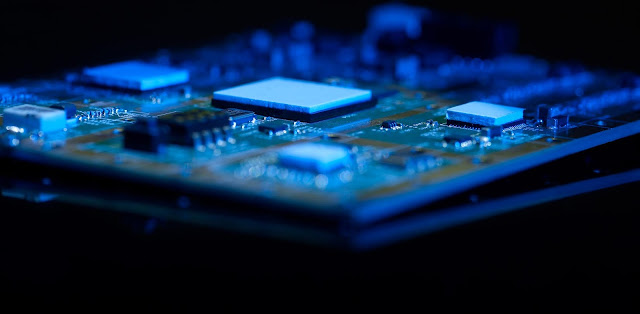

The

continuous evolution and miniaturization of electronic devices has pushed the

limits of heat dissipation and thermal management. As component density

increases and sizes decrease, excess heat generated during operation poses

serious risks if not transported out efficiently. This is where thermal

interface materials play a vital role by facilitating heat transfer between

components.

What are Thermal Interface Materials?

Thermal

interface materials

(TIMs) refer to any material designed to fill air gaps and promote thermal

conduction between two solid surfaces. They provide a thermally conductive path

to draw heat away from heat generating sources like processors, graphics cards,

and power delivery components to heat sinks and heat exchangers. Without a

proper TIM, the air gaps act as an insulator reducing heat transfer

drastically. Common TIMs include greases, gap pads, phase change materials, and

thermally conductive adhesives.

Importance of Thermal Interface Materials

The importance of TIMs cannot be overstated in electronics thermal management.

As device wattage increases with each new generation, efficient heat

dissipation away from hot spots becomes critical. Excessive temperatures can

severely impact performance, reliability and lifespan of components. Some key

impacts of inadequate thermal interface include:

- Increased junction temperatures lead to thermal throttling where processors

downclock speeds to maintain safe operating temperatures. This degrades

performance.

- Hot spots cause uneven heating which can lead to warping of components out of

alignment over time due to differences in coefficient of thermal expansion.

- Excessive temperatures accelerate aging and breakdown of solder joints and

interconnects. This negatively impacts reliability and reduces usable lifetime.

- In extreme cases, overheating can cause permanent damage to circuitry from

heat related failures if thermal shutdown thresholds are exceeded.

By filling microscopic air gaps, TIMs reduce thermal resistance enabling more

heat to flow out to external cooling solutions. This keeps critical components

within safe thermal design windows allowing them to run at optimal speeds.

Common Thermal Interface Materials

Greases: Thermally conductive greases are the most widely used TIMs. They have

a paste-like consistency and high viscosity which enables them to fill uneven

surfaces and air gaps easily. Greases also handle component flexing and

component replacement well. However, they tend to migrate or dry out over time

reducing performance.

Gap Pads: Thermally conductive gap filling pads are solid and phase change from

rubbery to rigid as they are compressed during installation. They maintain a

thin bonded interface but cannot self-heal if interface is compromised. Gap

pads offer durability but may leave small voids compared to greases.

Adhesives: Thermally conductive adhesives form strong metallurgical bonds

between surfaces. They offer durability and prevent shifting over multiple

thermal cycles. However, application can be messy and they cannot be reworked

easily if removed. Adhesives require very clean, flat mating surfaces for

optimal contact.

Phase Change Materials: PCM TIMs undergo reversible phase transitions from

solid to liquid at certain temperatures to improve heat conduction. They

maintain low resistance even during component flexing but have limited

temperature operating range before melting point is reached. Selection of right

PCM for application is important.

Applications of Thermal Interface Materials

With different properties, various TIMs fulfill requirements in different

applications:

- CPUs and GPUs: Greases are most common as they can fill rugged surfaces and

handle stresses of clamping without sacrificing performance long-term.

- Power Delivery Components: Gap pads provide thin, uniform bonds suited for

power modules and MOSFETs handling frequent power cycling stresses.

- LEDs and Laser Diodes: Thermally conductive adhesives form stronger bonds

suited for fragile optoelectronic packages requiring durability through thermal

shocks.

- ICs: Thin, low resistance greases or gap pads minimize thermal impedance for

high power density ICs without adding thermal mass.

- Avionics and Harsh Environments: Silicone based gap pads maintain flexibility

through wide temperatures ranges encountered in avionics and automotive.

- Server Racks: High performance thermal phase change materials maintain

integrity of tight gaps in crowded server racks.

Future of Thermal Interface Materials

The rapid pace of technology advancement brings new challenges for thermal

interface materials as well. Nanoparticle filled greases with thinner bonded

interfaces <10um are being developed to minimize resistance. Conductive

adhesives utilizing graphene and CNT fillers push the boundaries of thermal

conductivity. Liquid metal TIMs like gallium and indium alloys offer

unprecedented performance but require special considerations for compatibility.

As device densities increase with adoption of 3D packaging and multi-chip

designs, anisotropic interface materials able to conduct preferentially in

desired directions will become important. Development of self-healing, electrically

insulating TIMs able to autonomously repair interface damage also shows

promise. With continual innovation, thermal interface materials will remain a

crucial part of solutions ensuring electronics performance, reliability and

longevity in the years to come.

Thermal interface materials play a vital role in heat dissipation from modern

high-power electronics. By filling microscopic gaps, they facilitate thermal

conduction to external cooling solutions. With different types available,

selecting the right TIM suitable for the surface topology, stresses involved

and thermal requirements is important. Ongoing research brings new materials to

address future challenges. Proper selection and application of thermal

interface materials thus remains a cornerstone of effective thermal management

strategies.

Get more insights on this

topic: Thermal

Interface Materials

Comments

Post a Comment